| Standard Specifications | |

|---|---|

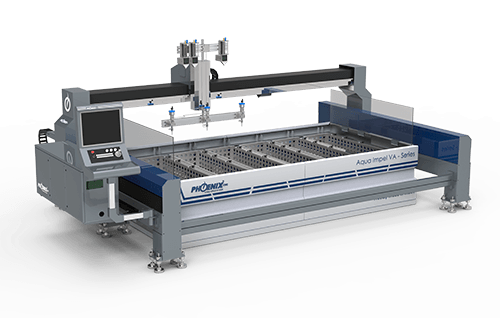

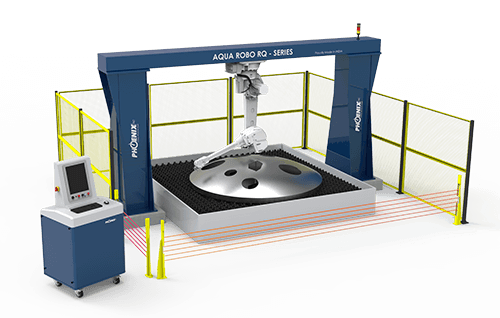

| Type of Structure | Presenting our advanced high-beam gantry structure, precisely crafted for large-format machines. Featuring an ingeniously low gantry end carriage height that minimizes inertia, ensuring exceptionally smooth linear movement. Combining high-speed acceleration with unmatched axial precision, it sets new industry standards for operational efficiency and performance. Its robust rigidity ensures an extended machine life, establishing a fresh benchmark in durability. Step into the forefront of industrial innovation – our high-beam gantry structure embodies strength, precision, and longevity, reshaping the global landscape of industrial machinery. |

| Type Of Cutting Processes | Abrasive Water Jet Cutting and pure water cutting |

| Material Of Construction | High-quality steel with anti-rust coating / SS304 |

| Number of Axis | 3 |

| Number of supported cutting heads | 2 |

| X-Axis Travel (Width) | 3500 / 4000 / 4500 / 5000 mm |

| Y-Axis Travel (Length) | 9000 / 10000 / 12000 / 14000 / 16000 / 20000 / 30000 / 40000 mm |

| Z-axis travel | 350 or more |

| Accuracy of XY Travel | +/- 0.2 mm/meter |

| Repeatability | +/- 0.2 mm/meter |

| Positioning accuracy | +/- 0.2 mm/meter |

| Max. Positioning Speed | 20 meters/minute |

| CAM / NC Software | MOST 2D (INDIA) / IGEMS(SWEDEN) |

| Controller | The ECS CNC Water Jet Controller from ITALY, featuring Phoenix CNC’s specialized enhancements, is widely regarded as the premier waterjet controller globally, renowned for its unparalleled piercing capabilities across a variety of materials. |

| Lubrication | Automatic Lubrication System with precise metering devices. |

| Drive Mechanism | The CNC machine’s drive mechanism for motion along the X and Y axis is driven by a pair of precisely synchronized A.C. digital servo motors from YASKAWA and PANASONIC, renowned manufacturers based in Japan. These motors are integrated with EtherCat communication capability, offering seamless coordination. They are coupled with precision low backlash planetary gearboxes made by NIDEC SHIMPO, another leading Japanese manufacturer. This advanced arrangement ensures not only smooth acceleration and deceleration but also precise control over profile-cutting speeds, making it an exceptional choice for high-precision operations |

| Linear Motion Components | HIWIN (TAIWAN) |

| Abrasive Metering System | Control Abrasive Flow Rate 0-1000 g/min |

| Advanced Operation | Joystick to operate X, Y, &Z – Axis |

| Capacity of Ultra-high-pressure Pump | Max. 90,000 PSI |