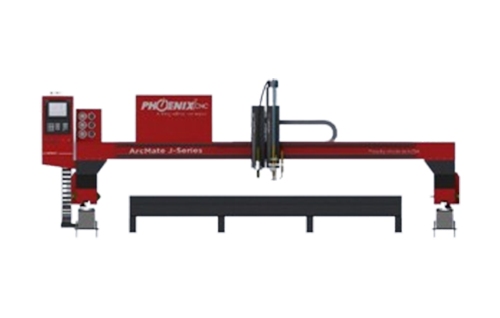

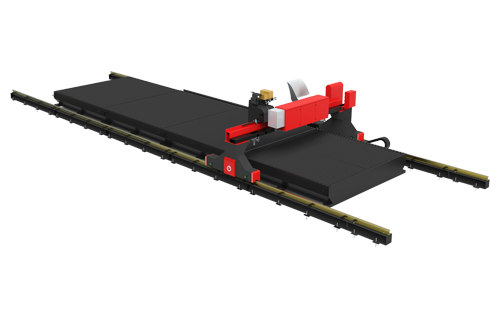

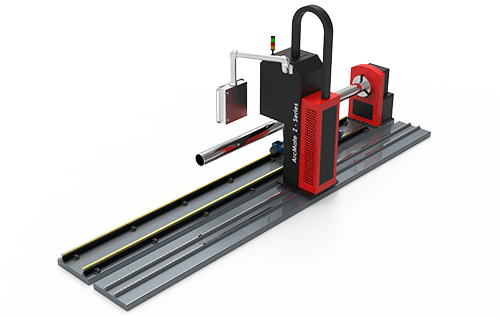

Presenting a trio of cutting-edge CNC plasma-cutting machines. Armed with a precision guidance system and robust construction, the Phoenix CNC lineup assures swift and accurate cuts while ensuring a cost-effective investment. Designed to be user-friendly and easy to operate, combined with exceptional post purchase assistance and support, the Phoenix CNC range emerges as the ultimate solution for cost-efficient, in-house metal cutting.

WHY Phoenix CNC Plasma?

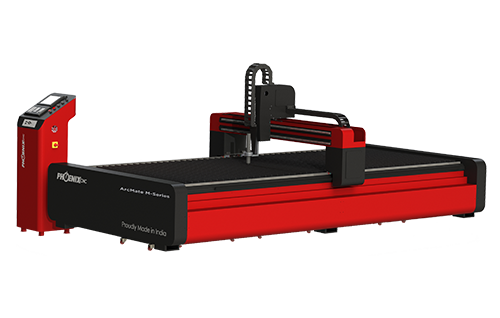

The Arcmate series has seen a decade of constant evolution. Since its inception, it has consistently progressed, earning its position as the foremost CNC cutting machine in the light industrial sector. With user friendly software, industry-leading functionalities, and a choice of six distinct base configurations, the Pro line-up is engineered to provide exceptional and dependable cutting performance, all within a durable and long-lasting framework.