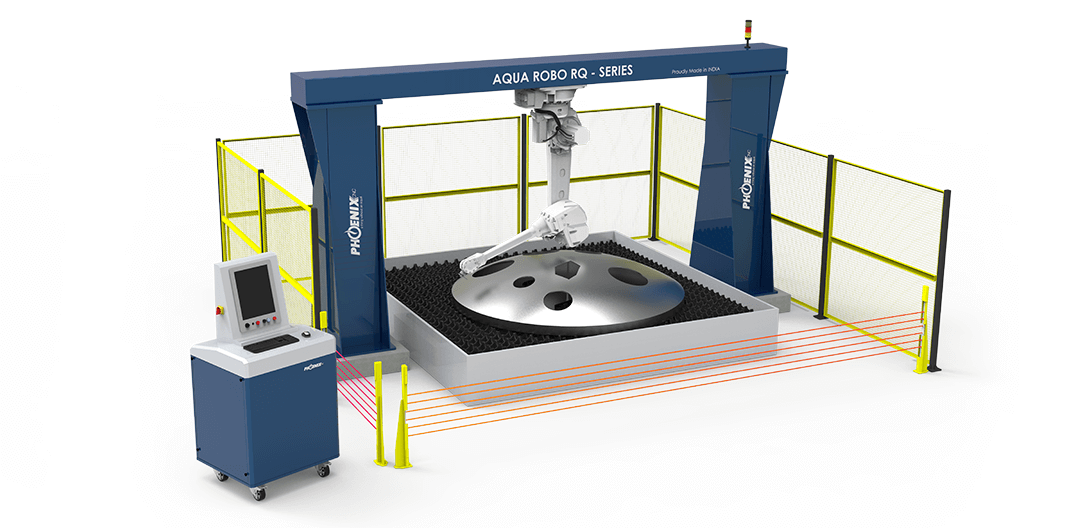

The robotic waterjet cutting system employs a high-precision 6-axis water-cutting robot as its primary actuator, accompanied by an ultra-high-pressure pump serving as the energy source for the cutting process. Workpiece positioning is achieved through the use of moulds, enabling the system to perform three-dimensional spatial cuts.

This system is meticulously designed to excel at cutting irregular space curves, offering a multitude of advantages, including enhanced efficiency, flawless incisions, and seamless compatibility. Its intelligent design and adaptable control system make it exceptionally versatile. By simply substituting the positioning moulds, it seamlessly transitions between various processing tasks, making it well-suited for small and medium-sized batch production across a diverse range of products. Its applications span across the automotive interior decoration and cutting of intricate surfaces.