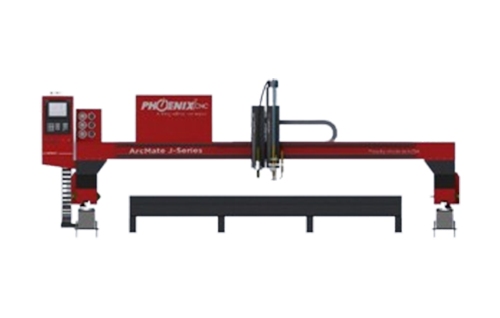

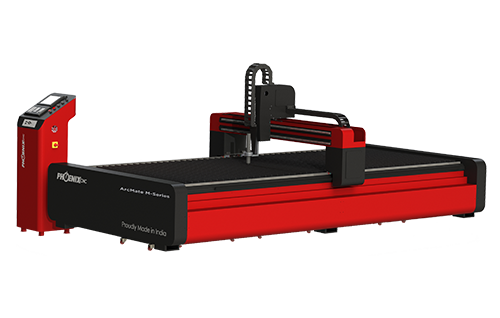

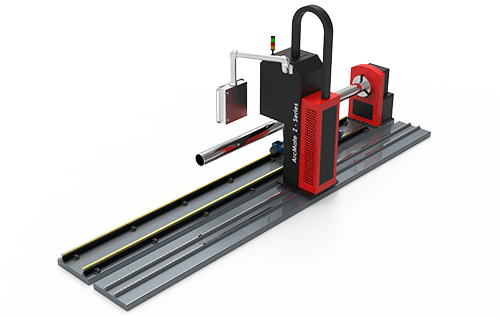

Unleash Precision and Power with Our Heavy Gantry High-Definition CNC Plasma/Oxyfuel Cutting Machine

Welcome to the forefront of cutting-edge manufacturing technology. Our Heavy Gantry High-Definition CNC Plasma/Oxyfuel Cutting Machine stands as a testament to precision, power, and unparalleled performance. Crafted with expertise and designed for excellence, this machine redefines what’s possible in the world of metal fabrication.