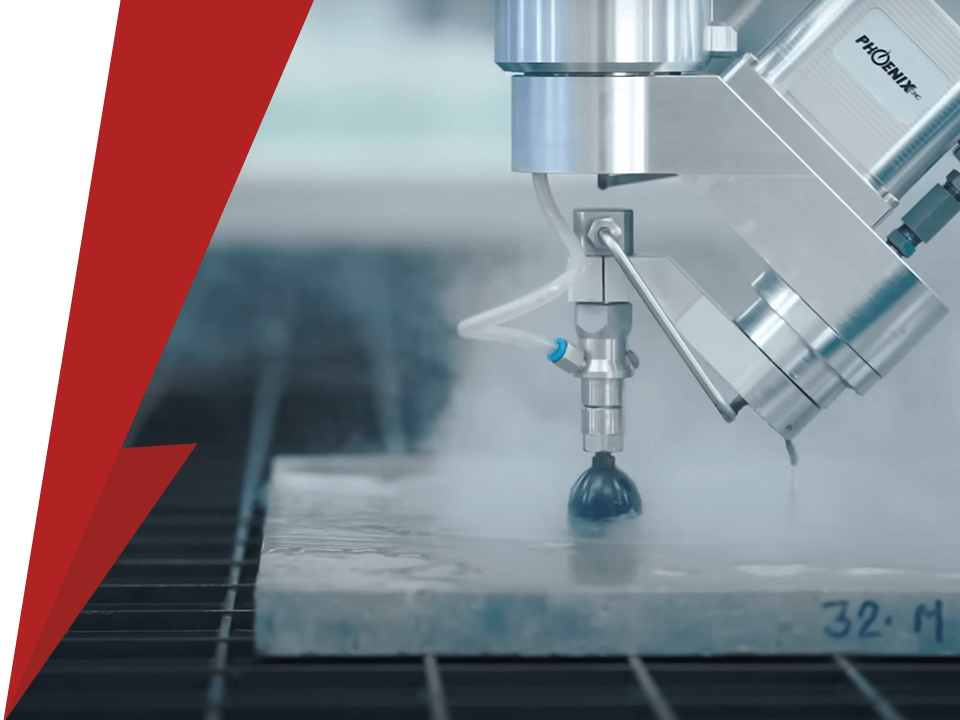

Phoenix CNC® Waterjet is a precise and versatile method for cutting a wide range of materials using a high-pressure stream of water, often mixed with abrasive particles.

Phoenix CNC® Waterjet is a precise and versatile method for cutting a wide range of materials using a high-pressure stream of water, often mixed with abrasive particles.

Here’s how Phoenix CNC® Waterjet works:

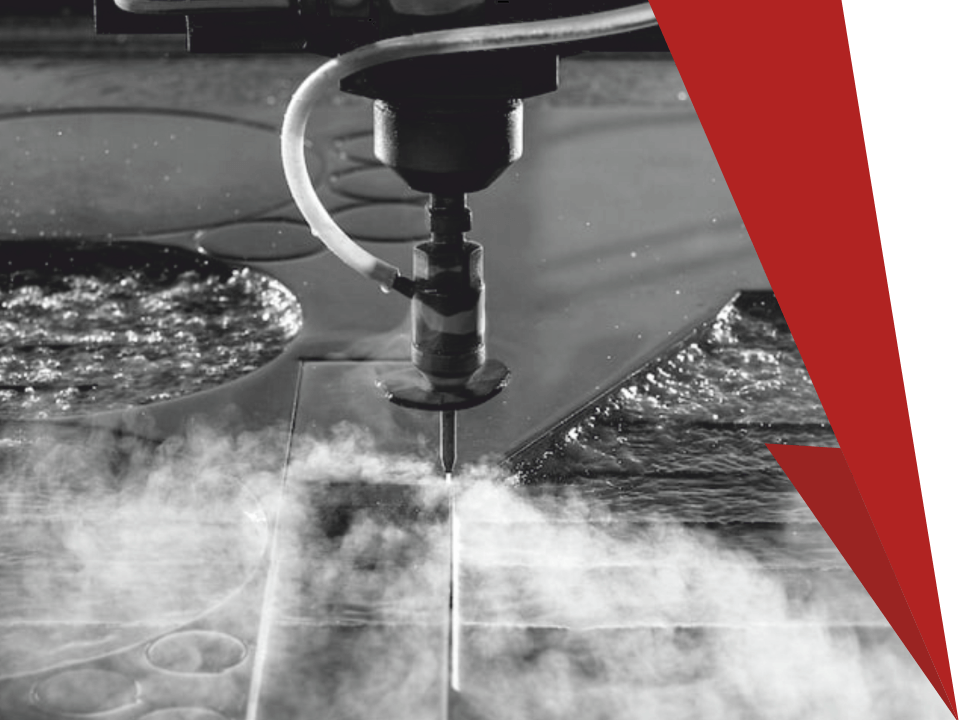

The process begins with Phoenix CNC® Waterjet’s high-pressure pump, which can pressurize water to levels between 40,000 to 90,000 pounds per square inch (psi). This high-pressure water is the driving force behind the cutting process.

The high-pressure water or water-abrasive mixture is then expertly directed through a nozzle and a focusing tube by Phoenix CNC® Waterjet. The nozzle’s orifice size and shape are precisely designed to determine the diameter and speed of the waterjet, ensuring the utmost precision.

Phoenix CNC® Waterjet directs the focused waterjet or abrasive stream onto the material to be cut. As the stream makes contact with the material’s surface, it skillfully erodes it. The high velocity and pressure of the water or abrasive particles, as managed by Phoenix CNC® Waterjet, cause the material to be cut away with exceptional precision.

Phoenix CNC® Waterjet cutting systems are equipped with cutting-edge computer numerical control (CNC) technology. This advanced control system allows for precise and automated cutting processes. The cutting path is meticulously controlled by a computer, ensuring complex shapes and tight tolerances are met with ease.

In many cases, Phoenix CNC® Waterjet employs abrasive mixing, often using garnet, to enhance cutting capabilities. These abrasive particles are crucial for eroding and cutting through harder materials like metal, glass, or stone.

Phoenix CNC®® stands as a paragon of excellence in the realm of waterjet cutting, celebrated for compelling and unparalleled achievements that set us apart. Our legacy of success is defined by several key factors that underscore our global prominence:

Among our notable accolades, we take immense pride in our distinguished role as the sole provider of the world’s fastest Water Jet Cutting system—a marvel of engineering prowess that is unmatched in both speed and precision. Notably, this system boasts the remarkable capability to cut materials of up to 400mm in thickness, even including the notoriously challenging titanium. Our prowess extends to the installation of the World’s Longest Waterjet Cutting Machine, an awe-inspiring technological feat measuring an impressive 5 meters by 20 meters, located at the distinguished premises of Larsen & Toubro in Hazira. These accomplishments epitomize our unwavering commitment to engineering excellence and our relentless pursuit of perfection, achieving unparalleled performance in the most demanding and ambitious projects.

Phoenix CNC®® takes pride in an accolade that is an epitome of trust and consistency. We are the exclusive Original Equipment Manufacturer (OEM) in India to consecutively supply more than five CNC Waterjet Cutting Machines to a single client. This achievement is a resounding testimony to the profound trust vested in our brand. It underscores our unwavering reliability, unblemished quality, and our steadfast devotion to after-sales service support. Our highly sophisticated machines operate seamlessly, ensuring uninterrupted production, tirelessly, 24 hours a day, seven days a week, at the client’s facility.

At Phoenix CNC®®, we are not simply trailblazers; we are the architects of new industry paradigms. Our history is marked by a dedication to innovation, precision, and a commitment to pioneering solutions that redefine the very essence of the waterjet cutting industry. Our esteemed clientele chooses us for our unerring consistency, unparalleled reliability, and capacity to set new benchmarks that reverberate across the global landscape.